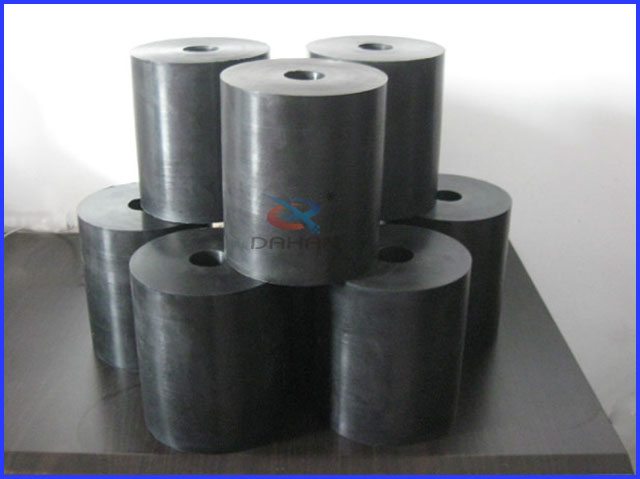

Vibration sieve composite spring is formed by metal helical spring and high quality rubber joint.Integrating the advantages of metal spring and rubber spring, overcame the metal spring rigidity. Overcoming the metal spring rigidity, high working noise and rubber spring bearing weight is small, poor stability of shape and mechanical properties of faults. Have a higher load capacity and large deformation, damping noise reduction effect is better, smooth work, resonance interval short, etc.Especially apply to mining, metallurgy, coal and other industries of large vibration equipment.

Vibrating screen compound rubber spring characteristics: shape restricted by metal helical spring, linear demand is high, weight is heavy, but the strength of the bearing load of large volume is not pure rubber spring can match.

The technical parameters of vibration sieve composite spring:

Vibrating screen compound rubber spring characteristics: shape restricted by metal helical spring, linear demand is high, weight is heavy, but the strength of the bearing load of large volume is not pure rubber spring can match.

The technical parameters of vibration sieve composite spring:

|

SizeD*H*d (mm) |

Outer diameter D

(mm) |

Inside diameter d (mm) |

Free height H (mm) |

The amount of deformation work FV

(cm) |

Stiffness KL (kg/cm) |

Working load (Pa) |

| φ90*150*φ38 | 90 | 38 | 150 | 2 | 150-350 | 300-700 |

| φ90*150*φ40 | 90 | 40 | 150 | 2 | 150-250 | 300-700 |

| φ148*260*φ80 | 148 | 80 | 260 | 3 | 180-600 | 500-1800 |

| φ148*270*φ80 | 148 | 80 | 270 | 3 | 180-600 | 500-1800 |

| φ150*250*φ80 | 150 | 80 | 250 | 3 | 180-600 | 500-1800 |

| φ150*250*φ92 | 150 | 92 | 250 | 3 | 180-600 | 500-1800 |

| φ150*265*φ80 | 150 | 80 | 265 | 3 | 180-600 | 500-1800 |

| φ150*265*φ92 | 150 | 92 | 265 | 3 | 180-600 | 500-1800 |

| φ155*280*φ62 | 155 | 62 | 280 | 3 | 180-600 | 500-1800 |

| φ155*280*φ75 | 155 | 75 | 280 | 3 | 180-600 | 500-1800 |

| φ155*290*φ60 | 155 | 60 | 290 | 3 | 240-660 | 700-2000 |

| φ155*290*φ62 | 155 | 62 | 290 | 3 | 240-660 | 700-2000 |

| φ155*290*φ75 | 155 | 75 | 290 | 3 | 240-660 | 700-2000 |

| φ155*290*φ80 | 160 | 80 | 290 | 3 | 240-660 | 700-2000 |

| φ160*236*φ94 | 160 | 94 | 236 | 2-3 | 250-1000 | 753-3000 |

| φ160*236*φ94 | 160 | 94 | 236 | 2-3 | 250-1000 | 753-3000 |

| φ160*240*φ94 | 160 | 94 | 240 | 3 | 300-1000 | 753-3000 |

| φ180*210*φ80 | 180 | 80 | 210 | 3 | 300-1000 | 753-3000 |

| φ180*220*φ80 | 180 | 80 | 220 | 3 | 300-1000 | 753-3000 |

| φ180*230*φ80 | 180 | 80 | 230 | 3 | 300-1000 | 753-3000 |

| φ180*230*φ85 | 180 | 85 | 230 | 3 | 300-1000 | 753-3000 |

| φ180*230*φ100 | 180 | 100 | 230 | 3 | 300-1000 | 753-3000 |

| φ180*240*φ80 | 180 | 80 | 240 | 3 | 300-1000 | 753-3000 |

| φ180*240*φ100 | 180 | 100 | 240 | 3 | 300-1000 | 753-3000 |

| φ180*270*φ80 | 180 | 80 | 270 | 3 | 300-1000 | 753-3000 |

Dahan spring advantages:

Modulus of elasticity is small, with large elastic deformation to absorb vibration and impact machine;Damping effect is significant and effectively reduces the resonance;Price low service life is long;Strong adaptability, waterproof and electricity not only, and can work normally in cold weather, bearing weight is big, strong stability;Low noise;High loading quantity, large deformation;The resonance zone is small, work stability, etc.

Modulus of elasticity is small, with large elastic deformation to absorb vibration and impact machine;Damping effect is significant and effectively reduces the resonance;Price low service life is long;Strong adaptability, waterproof and electricity not only, and can work normally in cold weather, bearing weight is big, strong stability;Low noise;High loading quantity, large deformation;The resonance zone is small, work stability, etc.