Vibration sieve is an important working parts to complete the screening process, the various parameters of various properties of materials, different structures sieve, sieve materials and machines are on the shaker screening capacity, efficiency, have an impact run rough and life, different materials, different places should use a different plate, in order to achieve the best results screening.

Sieve should have sufficient strength, wear resistance, the higher aperture ratio and easy plugging holes and other properties. Shaker vibration through the sieve materials of different shapes and sizes, under the action of the vibration force, the material is separated in different particle size, to achieve the purpose of classification.

Common forms sieve structure according to shape: ladder-shaped sieve (comb-shaped sieve), bars sieve, sieve slit,

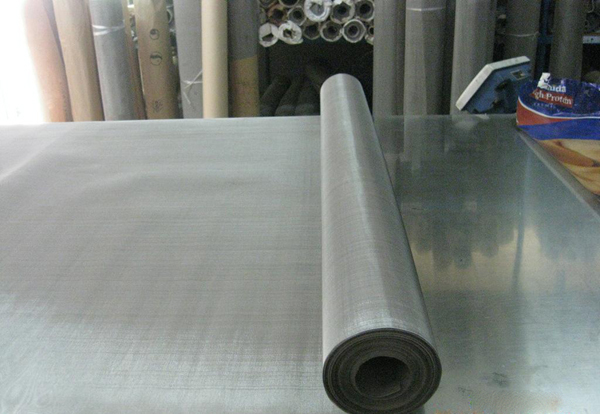

Special requirements for excellent corrosion resistance of stainless steel sieve of energy, acid, alkali, salt corrosion, can be adapted to oil wells, crevice corrosion and will not become bigger.

Sieve shaker Pass: rectangular hole, square hole, diamond hole, round hole, hexagonal hole, cross hole, triangle hole, a long hole, long waist hole, plum blossom hole, scale hole, hole pattern, pentagram hole, irregular holes, from the dark hole and so on.