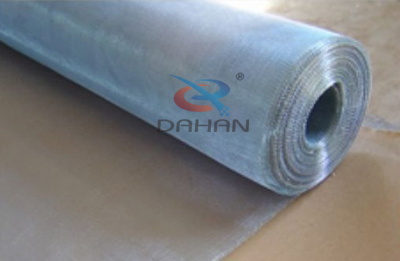

1, Material: stainless steel wire requires 304 braid, 304 high nickel content, resistance to acid corrosion, screen wire soft, not easy to break long life, ordinary 201 mesh nickel content at the end, not the anti-corrosion easy birth rust, material rigid, easy to break, easy to rust, so choose 304 stainless steel or 316L stainless steel.

2, Working network no tension, no close together to produce the parent net mesh bubbles, uneven tension is an important cause of premature failure of the screen.

3, When feeding excessive shaker work beyond the normal carrying capacity of the equipment change, causing the screen collapsed, are likely to cause damage to the screen.

4, Material hardness, are super-hard materials, while irregular material size structure, wear relatively large screen, this situation is not good to avoid screen damage, can only try to improve the life of the screen, first choose a more good mesh material such as 304 316, followed by a relatively large mesh sieve as a selectable punching board, there is can be graded screening, pay more labor two mesh, cushioning work network.

Xinxiang vibration machine is professional manufacturers - reliable and cheap.

304 Stainless steel screen mesh